In the world of skincare, precision and hygiene reign supreme. Enter skincare pumps, the unsung heroes that elevate our skincare routines, ensuring every drop is dispensed with effortless ease and utmost care. Join us as we delve into the fascinating realm of skincare pumps, exploring their types, intricacies, and the latest advancements that are revolutionizing the skincare landscape.

Types of Skincare Pumps

Skincare pumps are an essential component of many skincare products, providing a convenient and hygienic way to dispense the product. There are various types of skincare pumps available in the market, each with its unique features and benefits.

One common type of skincare pump is the lotion pump. Lotion pumps are designed to dispense thick, viscous products such as lotions, creams, and body washes. They typically have a large opening and a sturdy pump mechanism that can handle the thicker consistency of the product.

Lotion pumps are often found in bottles and jars of body lotion, hand cream, and facial cleansers.

Another type of skincare pump is the foam pump. Foam pumps create a luxurious, foamy lather when the product is dispensed. They are commonly used for products such as facial cleansers, shaving creams, and hand soaps. Foam pumps are known for their ability to create a rich, creamy lather that helps to cleanse and moisturize the skin.

They are also more economical as they dispense a smaller amount of product than lotion pumps.

Airless pumpsare a newer type of skincare pump that has gained popularity in recent years. Airless pumps prevent air from entering the container, which helps to preserve the product and prevent it from oxidizing or becoming contaminated. Airless pumps are often used for products that are sensitive to air exposure, such as serums, eye creams, and foundations.

They are also a good choice for products that are prone to bacterial growth.

Each type of skincare pump has its own advantages and disadvantages. Lotion pumps are versatile and can be used for a wide range of products, but they may not be the best choice for products that are very thick or viscous.

Foam pumps create a luxurious lather, but they may not be suitable for all skin types. Airless pumps are a good choice for products that are sensitive to air exposure, but they can be more expensive than other types of pumps.

When choosing a skincare pump, it is important to consider the type of product that will be dispensed, as well as the desired results. By understanding the different types of skincare pumps available, you can choose the one that is best suited to your needs.

Design and Functionality of Skincare Pumps

Skincare pumps are designed to dispense skincare products in a controlled and precise manner. They consist of several key components:*

-*Reservoir

The reservoir holds the skincare product and is typically made of plastic or glass.

-

-*Pump head

The pump head is the part that is pressed to dispense the product. It contains a piston that moves up and down to draw the product from the reservoir and dispense it through the nozzle.

-*Nozzle

The nozzle is the opening through which the product is dispensed. It can be designed to dispense different amounts of product, depending on the application.

-*Spring

The spring helps to return the piston to its original position after each pump.

Skincare pumps work by using a vacuum to draw the product from the reservoir and dispense it through the nozzle. When the pump head is pressed, the piston moves down, creating a vacuum in the reservoir. This vacuum draws the product up through the nozzle and out of the pump.

The amount of product dispensed is controlled by the size of the nozzle and the length of the piston stroke.Proper design is essential for effective and efficient product delivery. The pump head should be designed to fit comfortably in the hand and to provide a smooth and consistent pumping action.

The nozzle should be designed to dispense the correct amount of product for the intended application. The spring should be strong enough to return the piston to its original position after each pump, but not so strong that it makes the pump difficult to use.

Materials and Manufacturing of Skincare Pumps

The choice of materials and the manufacturing process play a crucial role in determining the quality, durability, and functionality of skincare pumps. Let’s explore the different materials used and the manufacturing steps involved in creating these essential components.

Materials Used in Skincare Pumps

Skincare pumps are typically made from a combination of materials, each with its own unique properties:

- Plastics: Polyethylene (PE), polypropylene (PP), and acrylonitrile butadiene styrene (ABS) are commonly used plastics due to their lightweight, durability, and resistance to chemicals.

- Metals: Stainless steel and aluminum are employed for their strength, corrosion resistance, and ability to withstand high temperatures.

- Glass: While less common, glass can provide excellent chemical resistance and transparency, allowing for easy product visibility.

- Rubber: Natural or synthetic rubber is used for gaskets and seals to create a tight fit and prevent leakage.

- Silicones: Silicone materials are known for their flexibility, biocompatibility, and resistance to extreme temperatures.

Manufacturing Process of Skincare Pumps

The manufacturing process of skincare pumps involves several key steps:

- Molding: The plastic or metal components are molded into their desired shapes using injection molding or die casting techniques.

- Assembly: The molded parts are assembled together, including the pump mechanism, spring, and actuator.

- Testing: The assembled pumps undergo rigorous testing to ensure they meet performance standards, including dispensing accuracy, leakage, and durability.

- Quality Control: Strict quality control measures are implemented throughout the manufacturing process to ensure the pumps meet the highest standards of quality and safety.

Applications of Skincare Pumps

Skincare pumps have become an essential dispensing mechanism in the cosmetic industry, providing several advantages for various skincare products. These pumps offer precise dosage, hygiene, and product preservation, making them ideal for a wide range of skincare formulations.

Types of Skincare Products Using Pumps

- Moisturizers:Pumps dispense the right amount of moisturizer, ensuring even application and preventing waste.

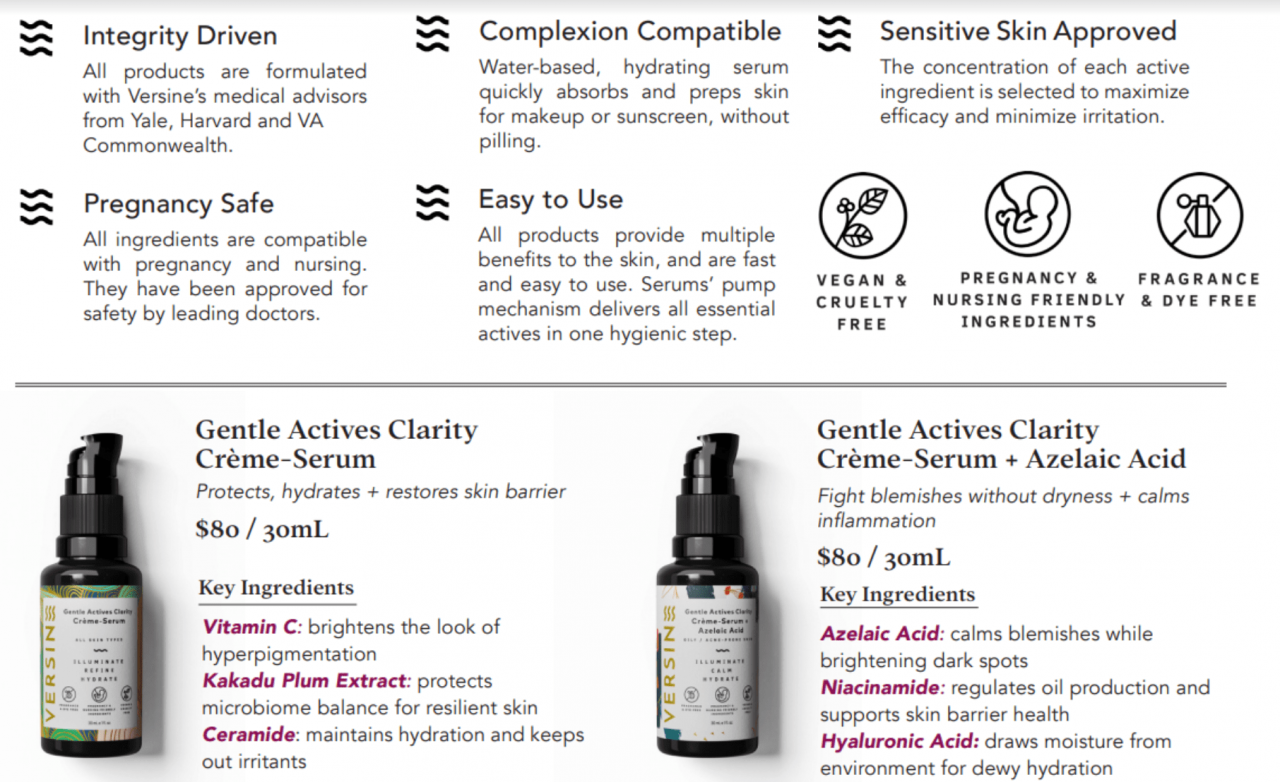

- Serums:Pumps help preserve the potency of concentrated serums by minimizing exposure to air and contaminants.

- Sunscreens:Pumps enable easy and even application of sunscreen, ensuring adequate coverage and protection.

- Cleansers:Pumps provide a controlled and hygienic way to dispense cleansers, preventing contamination and ensuring effective cleansing.

- Toners:Pumps help distribute toners evenly, avoiding over-application and ensuring optimal absorption.

Benefits of Using Pumps for Skincare Products

- Precise Dosage:Pumps dispense a specific amount of product, eliminating guesswork and ensuring consistent application.

- Hygiene:Pumps minimize direct contact with the product, reducing the risk of contamination and bacterial growth.

- Product Preservation:Pumps help protect skincare products from air, light, and moisture, preserving their efficacy and shelf life.

- Convenience:Pumps offer easy and effortless dispensing, making skincare routines more convenient and enjoyable.

Trends and Innovations in Skincare Pumps

The skincare industry is constantly evolving, and with it, the demand for innovative and effective skincare pumps. In recent years, we have seen a number of trends and innovations in the design and functionality of these pumps, driven by the need to enhance the user experience and product effectiveness.

One of the most significant trends is the move towards more sustainable and environmentally friendly pumps. This is being driven by the growing awareness of the impact of plastic waste on the environment, and the desire for consumers to use products that are more sustainable.

Emerging Technologies and Materials

In addition to the focus on sustainability, we are also seeing the emergence of new technologies and materials in the development of skincare pumps. These include:

- Airless pumps:These pumps help to prevent the product from coming into contact with air, which can help to preserve its freshness and potency.

- Foaming pumps:These pumps create a rich, foamy lather that can help to cleanse the skin and remove impurities.

- Dose-dispensing pumps:These pumps deliver a precise dose of product, which can help to ensure that the user is using the correct amount.

Enhanced User Experience and Product Effectiveness

These innovations in skincare pumps are not only improving the sustainability of these products, but they are also enhancing the user experience and product effectiveness. For example, airless pumps can help to prevent the product from becoming contaminated, which can lead to a longer shelf life.

For a flawless complexion, consider the outset skincare , a brand known for its gentle and effective formulas. If natural ingredients are your preference, explore trilogy skincare for a touch of nature’s goodness. For a luxurious skincare experience, indulge in huxley skincare , inspired by the Jeju Island’s pristine environment.

And to address specific skin concerns, osmosis skincare offers a range of medical-grade skincare solutions.

Foaming pumps can help to create a more luxurious and spa-like experience, while dose-dispensing pumps can help to ensure that the user is using the correct amount of product for their skin type.

Final Wrap-Up

As we conclude our exploration of skincare pumps, it’s evident that these seemingly simple devices play a pivotal role in enhancing our skincare experiences. From ensuring precise application to preserving product integrity, pumps have become indispensable tools in our quest for healthy, radiant skin.

As technology continues to advance, we can expect even more innovative and user-friendly pumps to emerge, further revolutionizing the way we care for our skin.

Detailed FAQs

What are the different types of skincare pumps?

Skincare pumps come in various types, including lotion pumps, foam pumps, airless pumps, and trigger sprayers, each designed for specific product formulations and application methods.

How do skincare pumps work?

Skincare pumps typically utilize a piston or diaphragm mechanism to draw product from the container and dispense it through a nozzle. The design ensures precise and controlled application, minimizing product waste and contamination.

What materials are commonly used in skincare pumps?

Skincare pumps are often made from durable and chemically resistant materials such as polypropylene, polyethylene, and aluminum, ensuring compatibility with various skincare formulations and preventing product degradation.

Leave a Reply